![]()

MXRR SUPERFINISHED & DLC COATED COMPONENTS

MXRR offers different

transmission and valve train components, processed with ISF and DLC coating.

This process is the same used in Formula 1 and all extreme motorsport

racing applications.

ISF

process:

ISF also known as ISOTROPIC

SUPERFINISHING is a patented process that allows to improve

dramatically surface characteristics of mechanical components. The ISF removes

all surface flaws derived from the machining and creates a non-directional

(from Greek “ISOTROPIC”) low Ra surface. This translates into a processed

surface without the asperities of the cutting tool.

The ISF process is carried out through polishing the components with special

ceramic media, vibrating in equipment and calibrated lubrication with dedicated

chemical compounds. The chemistry, which will not generate hydrogen embrittlement in high-strength steel parts, reacts with

part surfaces to produce a soft conversion coating. As the parts rolls in the

vibratory machine, the conversion coating is wiped

from peaks by the weight of the non-abrasive, high-density ceramic media,

exposing unreacted, underlying metal.

The peaks, being elevated, are wiped preferentially. Because the wiped coating was formed by reacting with the steel’s surface, coating

removal results in a lowering of the peak. Recessed valleys between the peaks

are untouched by the media, leaving the coating intact and the valleys

untouched. The valley left, grant optimized lubrication.

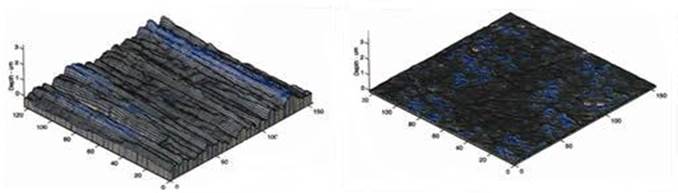

Typical

Surface Topography BEFORE ISF treatment:

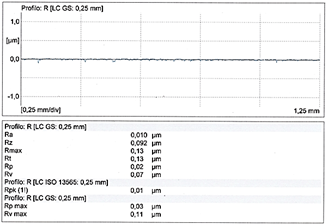

Typical Surface Topography AFTER ISF treatment:

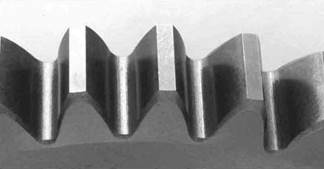

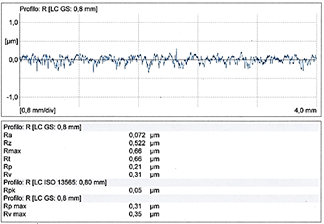

Standard Gear Profile BEFORE ISF treatment MXRR Gear profile AFTER ISF

treatment:

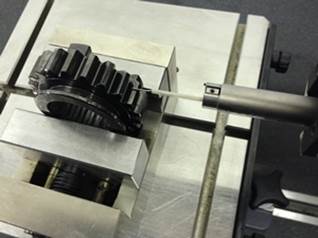

MXRR Gear profile during rugosity test:

Standard Gear Profile BEFORE ISF treatment MXRR Gear profile AFTER ISF

treatment:

Benefits:

Process is a value adding and

performance enhancing improvement to conventional machining operations such as

grinding and lapping. The extensive benefits of the ISF Process add value and

improve performance across a wide range of industries

-

Reduce Friction

-

Increase Part Durability

-

Improve Corrosion Resistance

-

Reduce Wear

-

Reduce Lubrication Requirements and Cost

-

Improve Oil Retention Properties

-

Reduce Contact and Bending Fatigue

-

Improve Pitting Resistance

-

Reduce Vibration and Noise

-

Reduce Applied Torque Requirements

-

Produce a Uniform Surface Finish

-

Produce a Superior Surface Finish

-

Minimize Overheating

-

Extend Component Life

MOTORSPORT EXTREME APPLICATIONS:

ISF processing is a “must” for

all serious RACING applications. All motorsports teams around the world use

this finishing process for all internal critical components of engines and

transmissions.

The key competitive advantages are the INCREASED

DURABILITY and DECREASED HEAT GENERATION.

DLC Coating Process:

MXRR

offers an additional feature to its kits: all ISF processed components are further improved by adding DLC coating.

DLC also

known as DIAMOND-LIKE-CARBON is a coating process, that deposits layers of are applied in plasma-assisted processes under vacuum with

an accuracy in the μm range. This advanced

coating technology contributes to enhanced performance and lifetime at the

highest competitive level.

DLC has

some of the valuable properties of diamond, including: high hardness, low friction, resistance to

wear, chemical inertness and smoothness. In common terms, DLC is harder than

natural diamond and slicker than "Teflon."

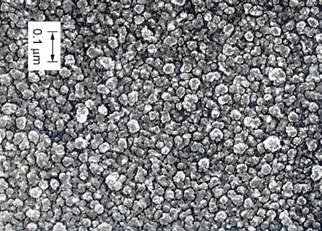

Diamond

like Carbon Ta-C coated surface at the microscope shows

as the structural elements are not crystallites but nodules of sp3-bonded

carbon atoms.

DLC coated

components have a surface up to 5 times harder than hardened steel. This

provides highly stressed components with excellent protection against wear and

thus increase their service lives. This hardness also makes parts more durable.

DLC coating protects moving parts from abrasion maintaining smooth movement

much longer than uncoated parts. Engines with DLC coated parts create more

horsepower, and have longer lifetimes from mechanical parts that rotate, slide,

and face other types of wear. For this reason, DLC is now standard practice on engine

parts in all Formula 1, racing cars, motorcycles, and boats.

DLC

coatings creates lower coefficients of friction. As friction is the enemy of

almost all moving parts, lowering it creates nearly universal improvement,

regardless of the application. Reduced friction also reduces the need for

lubrication, which can be a critical factor in extreme racing applications.

Benefits:

-

Friction losses reduced to a minimum

-

Measurably improved power output and reliability

-

Even under extreme conditions, DLC coated components live substantially

longer

-

Protection under lubrication starvation